Industrial Component Washer Manufacturers in India

Sonic Solutions is one of the reputed names among the leading Industrial Component Washer Manufacturers, Authorized AMC and Service Providers in India, offered customized component washer is designed to deliver superior cleaning performance across a wide range of production and industrial applications as per the customer's requirements. Our precision industrial part washer is used all around production and industrial applications for washing numerous parts and components, grease dissolution, oils and grime, to the level of cleanliness required as cleanliness standards before assembly or additional processing

Top Industrial Component Washer Manufacturers in India

Our Industrial Component Washers, designed by us, re-think this very essential necessity, redefining manufacturing both productivity and product quality. Strong in construction with gentle environmental concern, our high-standard washing systems bring your components to new levels of cleanliness standards, achieving productivity and dependability to level up at new height. We are used in car, aircraft, and food processing industries, where performance and quality mean cleanliness. Given below are its types, with the support of benefits and use as well.

Types of Industrial Component Washer:

Being as industrial component washer manufacturers and authorized AMC in India, has different types which as follow.

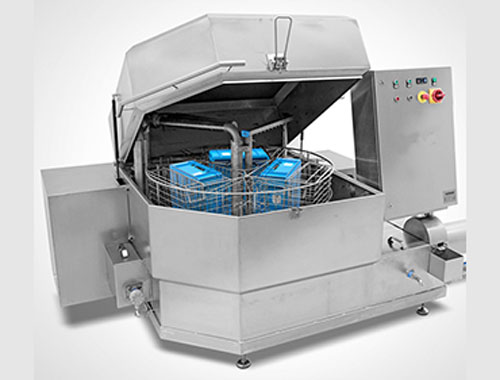

- Rotary Parts Washers: Industrial Washer include a rotation basket or platform and high-pressure spray jets to effectively clean the parts on all sides. Suitable for batch cleaning in bulk, these can efficiently and uniformly eliminate dirt like oil, grease, and debris.

- Spray Cabinet Washers: Enclosed equipment spraying warm cleaning liquids on the parts, spray washers are ideal for heavy-duty washing of bulkier or heavier parts. We may be fitted with rotating platforms as a step to ensure uniform coverage and effective loosening of debris.

- Ultrasonic Cleaning Machines: Ultrasonic cleaners apply high frequency ultrasonic energy to produce microbubbles that implode and clean stubborn grime off delicate and complex parts. Highly effective precision cleaning of delicate geometries without abrasion.

- Front Loading Industrial Component Washer: Front Loading Industrial Components Washer front-loaded washing machines are designed to give the utmost in ergonomic comfort and repeated use for medium to heavy-duty usage. Our washing machines are extensively used in factories where batch processing is a part of everyday requirement. As We are front-loaded, unloading and loading is even more convenient for them.

Technical Specification of Industrial Component Washer:

We have added below a technical sheet of Industrial Component Washer in India that provides more technical information such as:

1. Rotary Bin Cleaning Machine:

| Feature/Specification | Key Aspects |

|---|---|

| Machine Type & Loading | Front/Top Loading; single/multi-basket rotating system. |

| Automation Level | Semi-Automatic (manual load/unload, auto cycle) to Fully Automatic. |

| Cleaning Methodology | High-pressure hot water spray; detergent dosing. |

| Part Compatibility | Wide range of sizes/weights; various materials; intricate geometries. |

| Cleaning Cycle Features | Multi-stage (wash, rinse, dry); adjustable parameters; recipe management. |

| Liquid Management | Recirculated tanks; multi-stage filtration; auto oil skimming/dosing. |

| Drying System | High-volume hot air (70-120°C); forced convection. |

| Material of Construction (MOC) | SS 304 / SS 316L; heavy-duty components. |

| Control System & HMI | Advanced PLC & HMI; data logging. |

| Safety Features | E-stops, interlocks, overload protection; IP rated. |

| Energy Efficiency | Optimized heating/pumping; VFDs; insulation. |

| Maintenance & Serviceability | Easy access; self-diagnostics; modular design; local support. |

2. Ultrasonic Cleaning Machines:

| Feature/Specification | Key Aspects |

|---|---|

| Cleaning Principle | Ultrasonic cavitation (20-200 kHz); microscopic cleaning. |

| Machine Configuration | Single tank to multi-stage systems (wash, rinse, dry). |

| Ultrasonic Technology | Piezoceramic transducers; adjustable power/frequency; sweep/pulse mode. |

| Ultrasonic Generator | Digital, solid-state; auto-tuning; protection circuits. |

| Heating System | Precise temperature control (40-90°C). |

| Cleaning Solution Mgt. | Integrated multi-stage filtration; auto dosing; oil skimmers. |

| Material Handling | Manual or automated lifts/conveyors; custom fixtures. |

| Drying System | Hot air recirculation (70-150°C); vacuum drying; air knives. |

| Material of Construction (MOC) | SS 304 / SS 316L (polished/electropolished). |

| Control System & HMI | Advanced PLC & HMI; data logging; optional SCADA. |

| Safety Features | E-stops, interlocks, level/temp/overload protection; acoustic enclosures. |

3. Spray Cabinet Washers:

| Feature/Specification | Key Aspects |

|---|---|

| Machine Type & Loading | Front-loading; single/multi-basket; fixed or rotating turntable. |

| Automation Level | Semi-Automatic (manual load, auto cycle); optional auto load/unload. |

| Cleaning Methodology | High-pressure hot aqueous spray; detergent dosing; recirculation. |

| Spray Technology | Multi-directional, oscillating/rotating spray arms; adjustable pressure. |

| Part Compatibility | Wide range of sizes/weights; various materials; complex geometries. |

| Cleaning Cycle Features | Multi-stage (wash, rinse, dry); adjustable parameters; recipe management. |

| Liquid Management | Recirculated tanks with multi-stage filtration; auto oil skimmer/dosing. |

| Drying System | High-volume hot air recirculation (70-130°C); forced convection. |

| Material of Construction (MOC) | SS 304 / SS 316L. |

| Control System & HMI | Advanced PLC & HMI; data logging. |

| Safety Features | E-stops, interlocks, overload protection; IP rated. |

| Energy Efficiency | Optimized heating/pumping; VFDs; insulation. |

4. Front Loading Industrial Component Washer:

| Feature/Specification | Key Aspects |

|---|---|

| Machine Type & Loading | Front-loading, single chamber; rotating platform; custom baskets. |

| Automation Level | Semi-Automatic (manual load, auto cycle). |

| Cleaning Methodology | High-pressure hot aqueous spray; auto detergent dosing. |

| Spray Technology | Multi-directional nozzles; adjustable pressure; optional internal jetting. |

| Component Compatibility | Varied sizes/weights; multi-material; custom fixturing. |

| Cleaning Cycle Features | Multi-stage (wash, rinse, dry); adjustable parameters; recipe management. |

| Liquid Management | Recirculated tanks; multi-stage filtration; auto oil skimmer/dosing. |

| Drying System | High-volume hot air recirculation (70-130°C); forced convection. |

| Material of Construction (MOC) | SS 304 / SS 316L. |

| Control System & HMI | Advanced PLC & HMI; data logging. |

| Safety Features | E-stops, interlocks, overload/level protection; IP rated. |

| Energy Efficiency | Optimized heating/pumping; insulation; VFDs (optional). |

Benefits of Industrial Component Washer

As outstanding industrial component washer manufacturers in India, it is beneficial for different perspective which is given below.

- Higher Cleanliness Precision: The equipment is equipped with higher cleanliness that disintegrates oils, chips, grime, and other impurities unimaginable to eliminate with hand cleaning. Precision cleans parts up to the next operation such as assembly, coating, or inspection more accurately.

- Improved Quality & Life of Product: Industrial Washer of industrial parts removes defects and wear due to contaminants, improves product quality and integrity, and prolongs part life.

- Improved Efficiency: Automation of processes is cheaper in terms of processing and labor expense by a large percentage than conventional processes since less processing time, labor expense, and lost time for cleaning is involved. Parts are cleaned earlier and more uniformly and thus improved production process with fewer bottlenecks.

- Environmental & Safety Compliance: The majority of new industrial washers employ aqueous solutions and reduce corrosive chemicals and VOC emissions. It generates a clean working environment that is safe and facilitates easy compliance with strict environmental regulations.

- Cost Savings & Waste Reduction: Low-detergent and water-using cleaning operations and equipment like recycling and filtration systems lead to lower resource consumption and waste. Industrial Washer Extractor also economically advantageous to the operation in the long run.

Applications of Industrial Component Washer

Leading Industrial component washer Manufacturers in India and authorized AMC in India, it has different applications which is given below.

- Automotive & Aerospace: Cleaning engine blocks, transmission components, hydraulic components, aircraft structure components, and precision aerospace components to achieve maximum performance and safety.

- Medical Equipment & Healthcare: Sterilization and sanitizing of medical instruments and equipment, surgical instruments, and implants with very stringent sanitary and regulatory standards.

- Electronics & Semiconductors: Industrial Washing Machine High-precision cleaning of printed circuit boards, electronic modules, and sensitive assemblies where even the slightest particle will compromise performance.

- Manufacturing & General Engineering: Commercial Washer Extractor Cleaning of stampings, castings, machined parts, tools, and heavy equipment parts to remove cutting fluids, oils, and metal shavings after fabrication processes in industrial component washer manufacturers in India.

- Food & Beverage Processing: Sanitizing equipment for food and beverage processing, molds, and Industrial Parts Washing Machine containers to sanitation standards and to avoid cross-contamination of food and beverage processing.

Sonic Solutions is one of the Prominent Industrial component washer manufacturers, authorized AMC and service providers in India, are engineered to offer genuine and accurate cleaning solutions to a variety of manufacturing processes as per the customers requirements. By using such sophisticated cleaning chemicals, industries not only achieve squeaky cleanness of parts, but also achieve significant operating efficiencies, better product quality. Industrial Component cleaning Machine part washers’ clean parts of grease, oil, dirt and metal shavings up to their tolerance point before moving on to other subsequent important operations such as coating assembly or packaging. Get in touch with us today for more information.

FAQ

Ensures part quality, prepares surfaces for further processes (e.g., painting), prevents wear, and improves safety.

Parts are washed with heated cleaning solutions, rinsed, and then dried, with solutions often filtered and recycled.