Component Cleaning Machine Manufacturers in India

Sonic Solutions is one of the leading Component Cleaning Machine Manufacturers, Authorized AMC and Service Providers in India. We specialize in delivering advanced, high-performing industrial cleaning systems engineered for precision, performance and reliability. Our offered customized machines are designed to eliminate contaminants such as grease, oil, and dust. Component Cleaning Machine Manufacturer in India From the former speed and accuracy, our solution makes every and each one to perform at its highest levels of cleanliness, infusing life and performance. 3 Phase Industrial Component Cleaning Machine, bright world of productivity and trust is the duty of our new cleaning technology, to outshine even the best industry standards.

Types of Component Cleaning Machine:

Being as component cleaning machine manufacturers and authorized AMC in India, it serves different types which is given below.

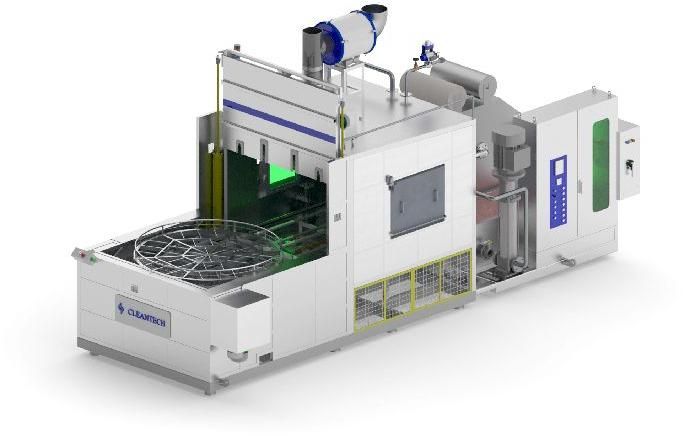

- Rotary Cabinet Washing Machines: Three Phase Component Cleaning Machine are batch type washing machines in which there is a revolving cabinet or basket in which the parts travel to immerse in cleaner and rinses. These can accommodate parts of variable sizes and clean effectively by mechanical action and spray.

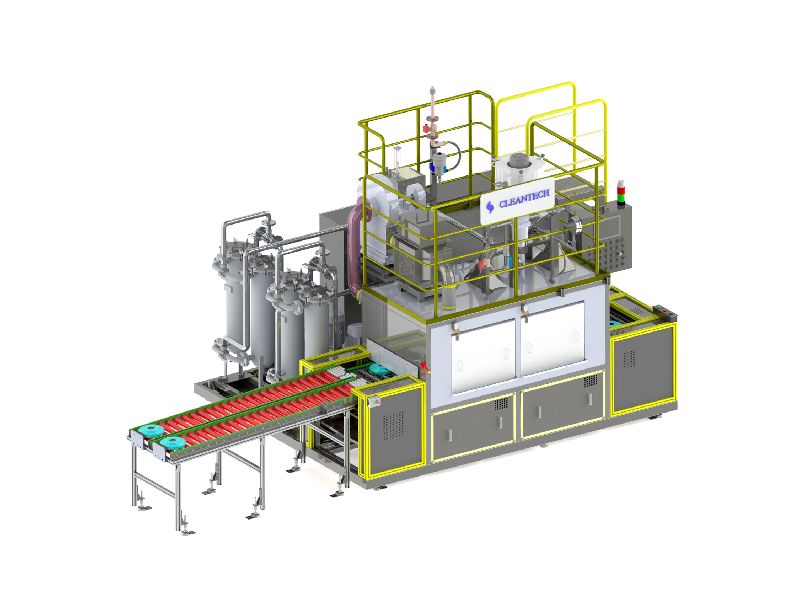

- Ultrasonic Cleaning Machines: The product is cleaned by ultrasonic high-frequency sound waves that create nano meter-diameter bubbles in a cleaning solution. Cavitation (bubble collapse) produces violent scrubbing action, stripping microscopic particles from the surface of sensitive parts.

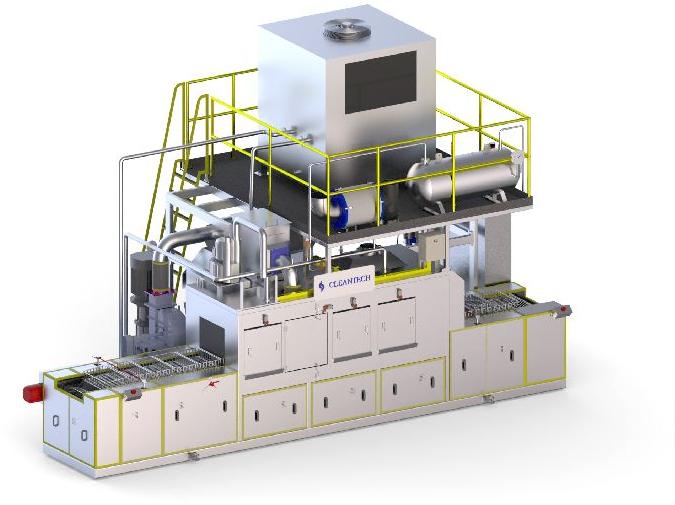

- Conveyorized Cleaning Machines: A conveyorized equipment installation on the production line that introduces automatic continuous bulk component cleaning. Components are constantly washed, rinsed, and dried to provide efficient and uniform bulk operation cleaning.

- Spray Washing Machines: 3 Phase Industrial Component Cleaning Machine Spray washers employ high-pressure sprays and soap and hot water to soak and clean off loose chips, oils, and debris completely from completed components. Rotary tables or conveyancing systems are usually employed by them to clean the parts complete and even.

Technical Specification of Component Cleaning Machine:

We have added below a technical sheet of Component Cleaning Machine in India that provides more technical information such as:

1. Rotary Cabinet Washing Machines:

| Feature/Specification | Key Aspects |

|---|---|

| Machine Type & Loading | Single chamber, front-loading; internal rotating platform. |

| Automation Level | Semi-Automatic (manual load, auto cycle); optional auto door. |

| Cleaning Methodology | High-pressure hot aqueous spray; auto detergent dosing. |

| Spray Technology | Multi-directional, high-impact nozzles; adjustable pressure; optional internal jetting. |

| Part Compatibility | Broad range of sizes/weights; custom fixturing. |

| Cleaning Cycle Features | Multi-stage (wash, rinse, dry); adjustable parameters; recipe management. |

| Liquid Management | Recirculated tanks; multi-stage filtration; auto oil skimmer/dosing. |

| Drying System | High-volume hot air recirculation (70-130°C); forced convection. |

| Material of Const. (MOC) | SS 304 / SS 316L; heavy-duty components. |

| Control System & HMI | Advanced PLC & HMI; data logging. |

| Safety Features | E-stops, interlocks; overload/level protection; IP rated. |

| Energy Efficiency | Optimized heating/pumping; insulation; VFDs (optional); heat recovery. |

| Maintenance & Serviceability | Easy access; self-diagnostics; modular design; local support. |

2. Conveyorized Cleaning Machines:

| Feature/Specification | Key Aspects |

|---|---|

| Machine Type & Config. | Tunnel/in-line design; various conveyor types. |

| Automation Level | Fully Automated (PLC controlled; HMI; SCADA/MES integration). |

| Cleaning Methodology | High-pressure spray, immersion, SPI, optional ultrasonic. |

| Spray/Immersion Tech. | Multi-directional manifolds; adjustable pressure; custom fixturing. |

| Cleaning Stages | Modular, segregated chambers (pre-wash, wash, rinse, dry, rust inhibit). |

| Liquid Management | Individual recirculated tanks; multi-stage filtration; auto oil/water/chemical control. |

| Drying System | Hot air recirculation tunnels (80-180°C); air knives; optional heat recovery. |

| Material of Const. (MOC) | SS 304 / SS 316L; heavy-duty components. |

| Control System & HMI | Advanced PLC & HMI; data logging; SCADA/MES integration. |

| Safety Features | Full enclosures; interlocks; light curtains; E-stops. |

| Energy Efficiency | Optimized heating/pumping; insulation; VFDs; heat recovery. |

3. Ultrasonic Cleaning Machines:

| Feature/Specification | Core Aspect |

|---|---|

| Process Control | High automation (PLC, HMI, SCADA), multi-stage, precise parameters. |

| Cleaning Media Mgt. | Recirculation, multi-stage filtration, auto dosing, oil separation. |

| Energy Efficiency | Optimized heating/pumping, insulation, VFDs, heat recovery. |

| MOC & Durability | Stainless steel (SS 304/316L), heavy-duty components. |

| Safety & Ergonomics | Interlocks, E-stops, enclosed design, noise control. |

| Maintenance | Easy access, self-diagnostics, modular design, local support. |

| Application Specific | Spray/ultrasonic tech, part handling (rotary/conveyor), drying. |

4. Spray Washing Machines:

| Feature/Specification | Key Aspects |

|---|---|

| Machine Type & Config. | Cabinet, Conveyorized, or Rotary Table types. |

| Automation Level | Semi to Fully Automatic (PLC, HMI, optional robotics). |

| Cleaning Methodology | High-pressure hot aqueous spray; auto detergent dosing. |

| Spray Technology | Multi-directional nozzles; adjustable pressure; internal jetting (optional). |

| Part Compatibility | Broad range of sizes/materials; custom fixturing. |

| Cleaning Stages | Multi-stage modular design (wash, rinse, dry, etc.). |

| Liquid Management | Recirculated tanks; multi-stage filtration; auto oil/water/chemical control. |

| Drying System | Hot air recirculation (70-150°C); air knives; optional heat recovery. |

| Material of Const. (MOC) | SS 304 / SS 316L; heavy-duty components. |

| Control System & HMI | Advanced PLC & HMI; data logging; optional SCADA/MES. |

| Safety Features | Full enclosures; interlocks; E-stops; IP rated. |

| Energy Efficiency | Optimized heating/pumping; insulation; VFDs; heat recovery. |

| Maintenance & Serviceability | Easy access; self-diagnostics; modular design; local support. |

Benefits of Component Cleaning Machine

Serve as well known component cleaning machine manufacturers in India, it gives different benefits as per requirement which is given below.

- Increased Component Life: Single Stage component Cleaning Machine By preventing wear and corrosion through effective removal of abrasive particles, oil, and dust, component cleaning machines avoid wear and corrosion. Successful machine cleanliness significantly enhances operational part life, minimizing maintenance and replacement requirements.

- Improved Productivity & Efficiency: Trained cleaning operations involve less men input and clean at a greater percentage. 3Phase Converized Component Cleaning Machine increases the quality of the efficiency rate process, reduces downtime, and allows increased levels of production to be achieved, hence more output and profitability.

- Enhanced Product Quality: Cleaned parts translate to maximum performance and reliability of end products. The machines provide consistent high-quality cleanliness, leading to enhanced product quality, lower defect, and increased customer satisfaction.

- Cost Saving: While initially it is a nominal cost, the Industrial Component cleaning Machine become long-term capital in the sense that These save man-hour cost, save soap and water by being cleaned and reused, and cut on rework due to improper cleaning.

- Environmental Safety & Compliance: The eco-friendly, water-based cleaners replace unnecessary use of harmful chemicals in the next generation part cleaning machinery. Automotive Component Cleaning Machine Enhanced employee safety through automation and green compliance advantage makes them a green choice for businesses.

Applications of Component Cleaning Machine

As component cleaning machine manufacturers in India and authorized AMC in India, it is applicable in different siters for safety and performance which is given below.

- Automotive Industry: Industrial Parts Cleaning Equipment Applied to engine block, transmission part, brake part, and other parts cleaning in manufacturing, Single Stage component Cleaning Machine remanufacturing, and repair for optimum performance and life.

- General Manufacturing & Machining: Three Phase Component Cleaning Machine Used most often to degrease and deburr machined components, clean cutting fluid, chips, and oils prior to assembly, coating, or further manufacture.

- Aerospace & Defense: To Industrial Parts Cleaning Machine degrease parts with critical components, hydraulic components, and structural components where trace contamination will compromise safety and performance.

- Medical Equipment: To Component Cleaning Machine Manufacturers in India sterilize and clean surgical equipment, implants, and other medical devices to high levels of hygiene and safety.

- Electronics Industry: To Component Cleaning Machine clean printed circuit boards (PCBs), electronic assemblies, and electronic components to eliminate flux residues, solder paste, and other contamination for end electrical conductivity and reliability.

One of the leading component cleaning machine manufacturers, authorized AMC and service providers in India, we as Sonic Solutions offering the new technological component cleaning machine. Whether the high standards of the automobile and aviation industry or the required cleanness of medicine and electronic manufacturing, the machine's output here is superior. Component Cleaning Machine Manufacturer machine plays a critical role in maintaining product quality and operational efficiency across sectors like automotive, aerospace, precision engineering, electronics and heavy machinery. 3 Phase Industrial Component Cleaning Machine Manufacturer preparing parts for coating, welding or packaging, our component cleaning system ensures that every surface is thoroughly cleaned to meet both industry regulations and customer specifications. For more information about our component cleaning machine, contact us today.

FAQ

A specialized industrial machine designed to thoroughly remove contaminants (oils, dirt, chips, etc.) from parts and components.

Ensures product quality, prepares surfaces for further processes, prevents wear, and improves safety and compliance.